We manufacture components used in automotive, medical, and industrial devices that impact the performance of products worldwide. Our commitment is to control and continually improve on the processes used in manufacturing our components to satisfy the demands of our customers. The commitment to quality includes the engagement of all company employees to focus on improving our QMS.

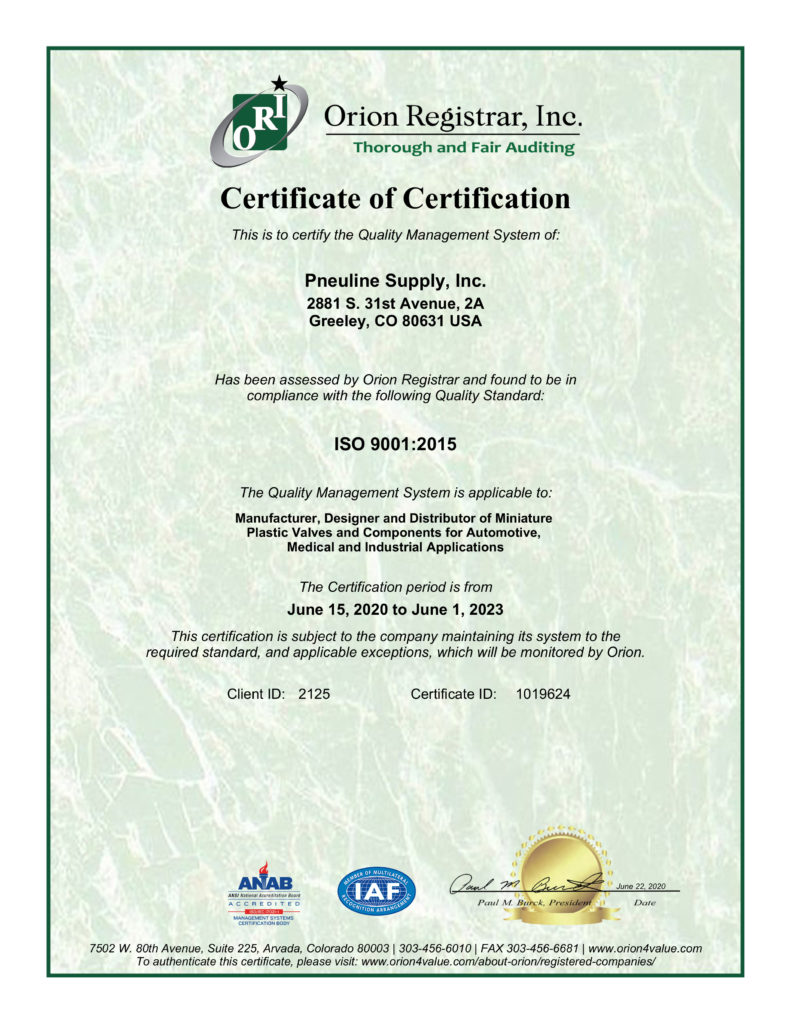

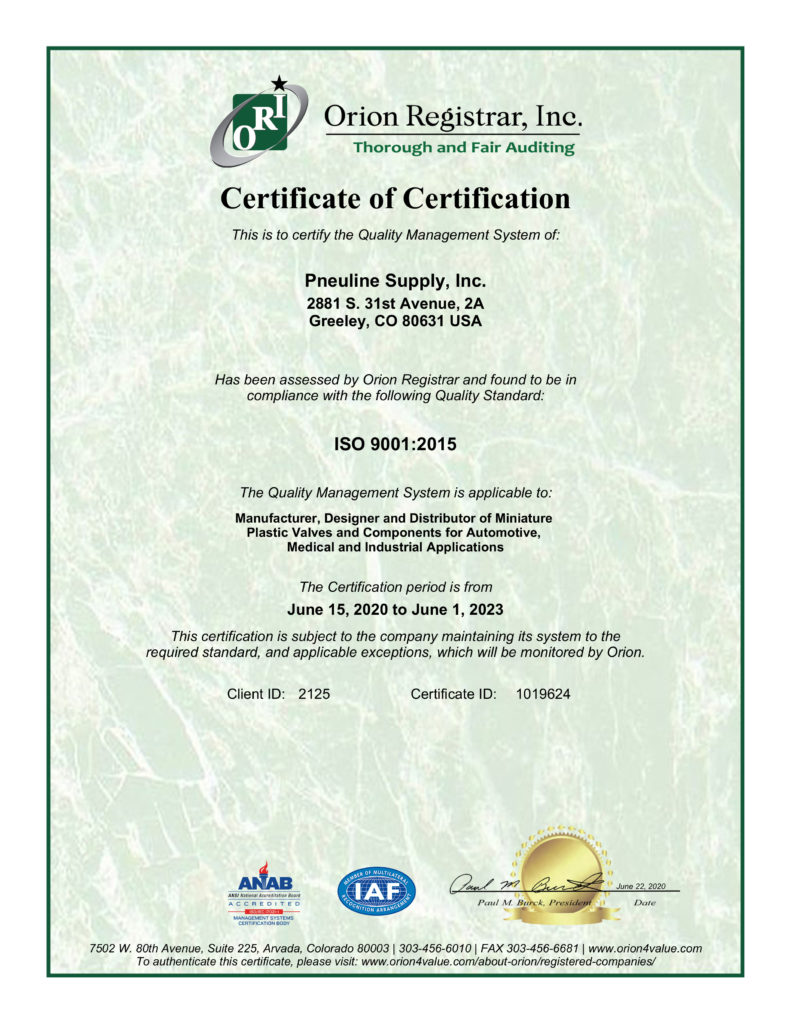

Certifications

Pneuline Supply proudly complies with ISO 9001:2015 Quality Standards

For over a decade, Pneuline Supply, Inc. has been producing custom assemblies for our customers for special applications such as: Automotive Injectors, Check Valves for chlorination applications, Ozone flow control, Pick-up Tubes for liquids, as well as special orifices to name a few. Pneuline produces and supplies thousands of different product types and millions of parts per year to our customers all over the world. Last year we produced over 2 million check valves, hundreds of thousands of connectors, tens of thousands of filters, and thousands of various assemblies.

Design

Our engineering and design department uses the latest in computer hardware and software technology to create designs from concept to finalized products.

Molding

Custom plastic molding capabilities include various material and size options. Currently we manufacture plastic diaphragm check valves, spring-loaded check valves, bulkheads, lab disconnects, elbows, straight connectors, tee connctors, inline filters, pickup filters, normally closed check valves, and adapters. We utilize our state-of-the-art electric plastic injection molding machines to manufacture plastic components to meet unique product specifications and requirements.

Production

Our skilled production team assembles our manufactured components into finished goods using controlled procedures for accurate and consistent product which is inspected through-out the production process to ensure that only reliable product reaches the customer.

Testing

We 100% leak test our manufactured plastic check valves. This testing coupled with regular quality verifications of the ultrasonic welds and dimensional verification ensures that each of our customers receive the highest quality product. Our testing equipment is certified and calibrated periodically by iso-certiified calibration labs to achieve consistent measurements.

Marking

Our fast laser marking systems give us the capability to label product with high-speed, high-resolution quality of unique identifiers such as lot tracking codes, part numbers, barcodes, qr codes, company branding, or any other desired type of identifier.

Packaging

We shipped over 2,000,000 check valves last year and expect to surpass that amount this year as well as every year from now on. We offer customized shipping labels per customer requirements and specifications.